450 Entryway

Before . . .

There wasn’t anything really wrong with this entryway, there just wasn’t anything really right about it either. Working closely with John and Mike at John Wingfelder Architects we came up with a design that vastly improved the overall facade of our home.

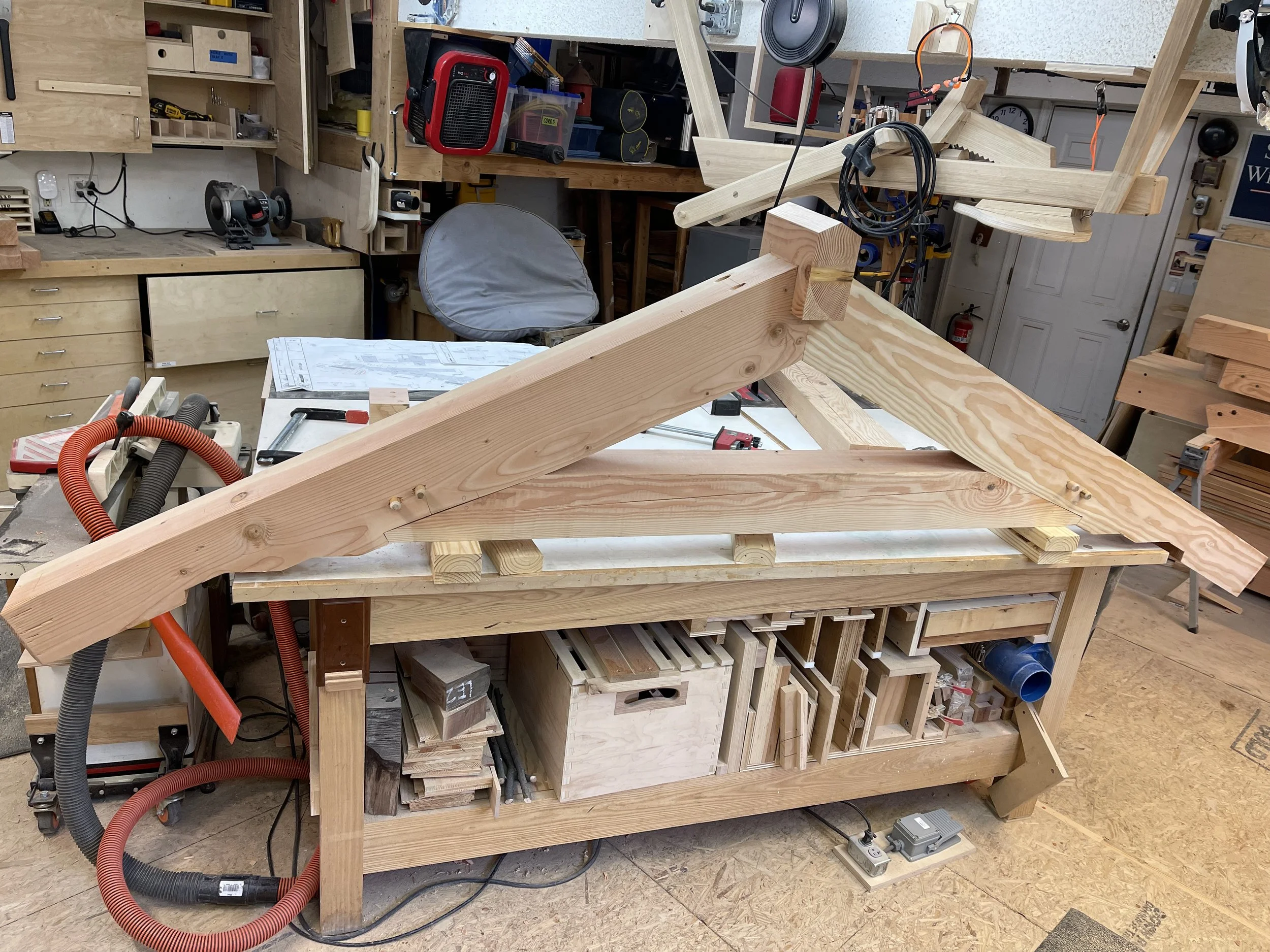

Prefabrication

This was a complicated build. The drawings from John & Mike were exceptional — mind boggling so. but the shear scale of the timbers, their weight, and, let’s be fair, cost, meant that careful planning was called for. Also, the tools I used for cabinet building would not be sufficient for the enormous mortices & tenons needed when joining 8x8 timbers.

I have to admit I was a bit sad when the last timber was cut, morticed, and test fit complete. It was great fun figuring all of this out.

Building

There was no way I was going to put all of this together without help. Some of the timbers weighed as much as 100 lbs. making assistance an absolute necessity. But more than that, everybody that stopped by to see my progress with the prefabrication or listened patiently to my updates wanted to be a part of the final build. So we set a date on an impossibly hot summer day, ordered up some bar-b-que (and an ice-cream truck), pitched a tent, and invited one and all to come and help.

It was a great day and each peg was hammered home by someone different. We had almost as many site-supervisors as actual workers and that was, um, interesting. But in the end we all got to be a part of this small but very interesting and complex assembly.